Peter Huston, Stacie White and their 80 or so colleagues at Fusion Specialties were just wrapping up before the Thanksgiving holiday last year when Barrie Bamberg, executive print producer, with Crispin Porter + Bogusky (CP+B) called. That much was business as usual. Fusion has supplied in-store mannequins for CP+B client Old Navy and other Gap Inc. brands for years. But “usual” was no part of that late November conversation.

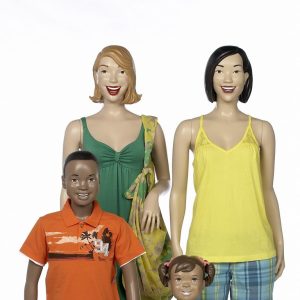

“All Barrie would say was that CP+B was planning a fully integrated marketing campaign for Old Navy. She provided us with a brief of the original concept and asked us to work up some alternatives for the in-store mannequins,” says Huston, Fusion’s executive vp. What the creative agency didn’t say initially was that, if Old Navy’s leadership okayed the SuperModelquin pitch, it would be placing the largest order in Fusion’s history and challenging the company to fast-track production of 13,000 mannequins with attitude for Old Navy stores nationwide.

Old Navy gave the go-ahead shortly after and White, Fusion’s creative director, along with the company’s product development manager, two sculptors and four prototype artists forsook turkey and time off to formulate and implement production strategies for delivering the record-breaking order in record time.

HEAD START

“The first major challenge was taking the 3-D computer files and prototypes of the heads created by special effects expert, Legacy Effects, and making them work on our previously-designed bodies,” says White. “There was no time for trials or revisions.”

Fusion had the advantage of having developed headless urethane male and female mannequin bodies specifically designed to Old Navy’s fit size specs and clothing styles just two years ago. That cut front-end development time. But the stylized heads provided for the campaign didn’t fit the existing models’ necks. White reached reach out to several vendors to “grow” the heads. “Time was so tight that no one vendor was able to meet our dates for all of the characters,” she says. “Knowing each vendor would supply us with a slightly different level of finish, we had to be prepared to work with what was provided in a timely and effective way.” Once the heads arrived, sculptors took over to ensure they were scaled to fit seamlessly.

The mannequins were molded, subjected to quality control review and married with their bases. “Normally, we do that at the end of the production process. But because the SuperModelquins had to be painted (to achieve the right skin tones), it was more efficient to have them standing. We looked at every step in the process to find efficiencies, from how the mannequins were packaged to minute differences in the sizes of base plates,” says Huston.

For more on the SuperModelquins, click here.

Photo Gallery1 week ago

Photo Gallery1 week ago

Headlines3 days ago

Headlines3 days ago

Headlines1 week ago

Headlines1 week ago

Headlines1 week ago

Headlines1 week ago

Headlines1 week ago

Headlines1 week ago

Designer Dozen1 week ago

Designer Dozen1 week ago

Headlines1 week ago

Headlines1 week ago

Headlines1 week ago

Headlines1 week ago